Troubleshooting Common Heat Pump Issues: Practical Fixes for Miami County Homes

Heat pumps move heat instead of creating it, which makes them efficient for both heating and cooling. But things can go wrong and leave your home feeling uncomfortable. This guide walks Miami County homeowners through the most common heat pump problems, why they happen, and safe, practical checks you can do before calling for service. You’ll learn to spot issues like weak airflow, short cycling, odd noises, icing, and cold air in heat mode. Each section gives clear diagnostics, step-by-step checks you can try at home, short safety notes, and when it’s time to call a trained technician. For more information, consider our heat pump maintenance services.

Why Is My Heat Pump Not Heating or Cooling Properly?

If your heat pump isn’t getting to the temperature you expect, it’s usually because heat isn’t being moved efficiently. That can come from poor airflow, low refrigerant, electrical faults, or control problems. Some causes are quick checks you can do yourself—filters, vents, or thermostat settings—while refrigerant leaks or compressor problems need a pro with tools. Knowing the likely causes helps you run safe DIY checks and decide when to call a technician. Below we list what to watch for, common causes, home troubleshooting steps, and red flags that require professional help.

What Are the Symptoms of a Heat Pump Not Heating or Cooling?

Symptoms are the clues that point to the problem: vents that blow air at the wrong temperature, a unit that runs constantly without hitting setpoint, or rooms that are unevenly heated or cooled. Other useful signs include weak airflow from vents, strange cycling patterns, and visible frost or pooling around the outdoor unit. Easy checks you can do: feel the supply air, compare it to the thermostatsetpoint, and confirm the indoor fan is running at the correct speed. Catching problems early saves energy and helps narrow whether the issue is airflow, controls, or a refrigerant/equipment fault.

What Common Causes Lead to Heat Pump Heating or Cooling Failure?

Common causes include restricted airflow from dirty filters or closed vents, incorrect thermostat settings, low refrigerant or leaks, and failed components such as compressors or reversing valves. Electrical problems—tripped breakers or bad contactors—can also interrupt operation and mimic mechanical faults. Some signs, like oil residue or persistent frost, point strongly to refrigerant or compressor issues that need a technician. Knowing these cause-and-effect relationships helps you run focused, safe checks that speed up diagnosis. For more information on maintaining your system, you can explore our HVAC maintenance plan.

How Can I Troubleshoot a Heat Pump That Isn’t Heating or Cooling?

Always start with safety and the simplest checks that don’t involve opening electrical panels. Confirm the thermostat mode and setpoint, inspect and replace a dirty air filter, and make sure supply vents and returns are open. Check the outdoor unit for debris and look for ice on refrigerant lines (normal during defrost cycles is different from persistent icing). Confirm the breaker hasn’t tripped and the unit has power. If those checks don’t restore performance in one monitoring cycle, record details—vent temperatures, noises, breaker trips—to share with a technician who can test refrigerant and electrical components. These ordered steps reduce unnecessary service calls and help the technician focus on the real problem.

Quick-reference table: the chart below links homeowner observations to likely causes, simple DIY checks, and when to call a pro. Use it to prioritize steps and report useful details when you schedule service.

| Component / Symptom | Observable Sign | Likely Cause(s) | DIY Check | When to Call Pro |

|---|---|---|---|---|

| Weak or no warm/cool air | Low vent temperature or minimal airflow | Dirty filter, closed vents, fan motor issue | Replace or inspect filter, open vents, listen for fan | If airflow stays low or fan is noisy |

| System runs but no temperature change | Long run times despite thermostat calls | Low refrigerant, compressor fault, reversing valve issue | Confirm mode and that outdoor unit is running | If you see oil, repeated long runtimes, or compressor noise |

| Uneven room temps | Some rooms much warmer/cooler than others | Duct problems, zoning issues, blocked returns | Check vents and returns; inspect balance dampers | If ducts need access or imbalance continues |

| Outdoor unit iced (not normal defrost) | Heavy ice on unit or frost on lines | Low refrigerant, failed defrost control, airflow restriction | Clear light snow and improve airflow | If icing repeats after thaw or oil residue appears |

This table turns symptoms into next steps and makes clear when a pro’s diagnosis is necessary to restore safe, reliable operation.

How Do I Fix a Heat Pump That Is Freezing Up During Ohio Winters?

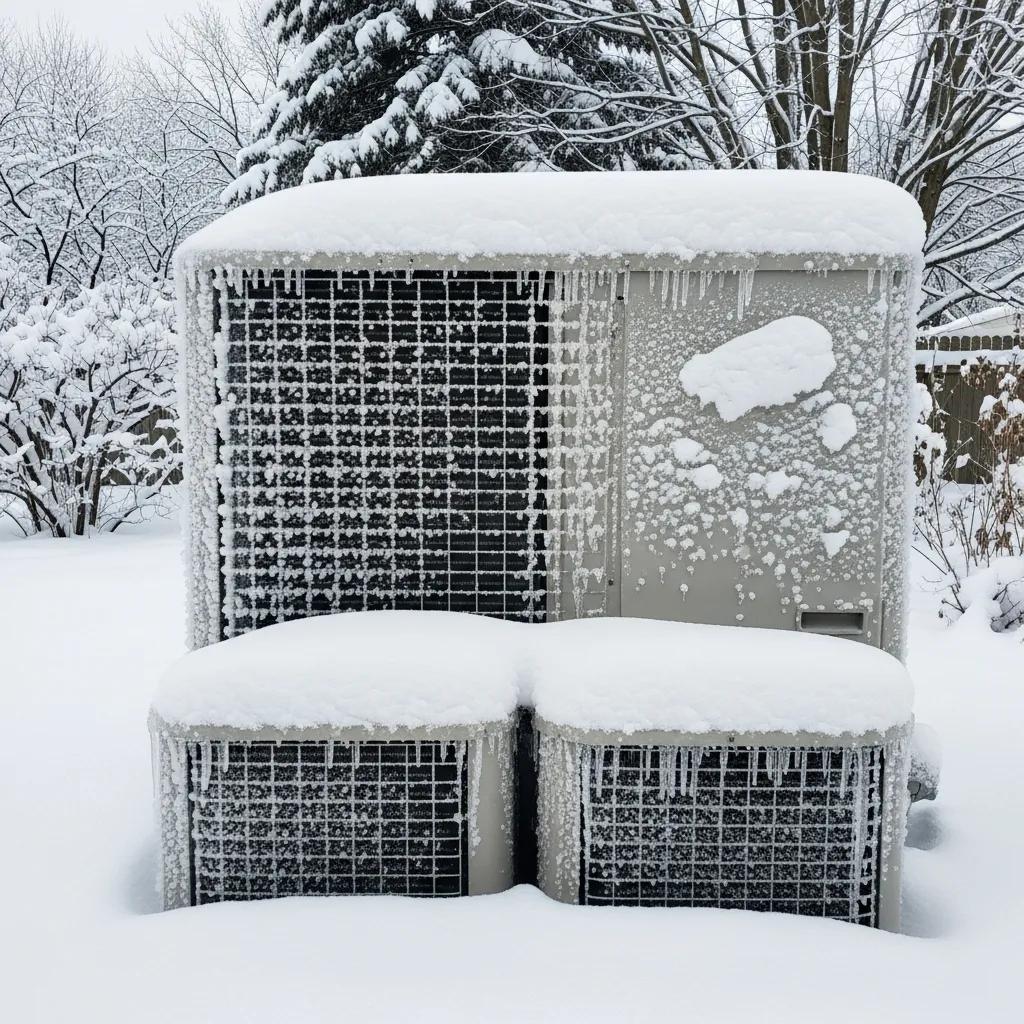

Ice builds when the outdoor coil can’t exchange heat properly. Normal defrost cycles remove light frost, but persistent ice usually means restricted airflow, low refrigerant, or a failed defrost control. In Miami County, snow, freezing rain, and debris packed around the unit increase the chance of abnormal icing. Start with safe thawing and airflow checks before assuming electrical or refrigerant repairs. The sections below explain causes, homeowner-safe steps, and clear triggers to call a technician.

What Causes Heat Pump Freezing and Ice Build-Up?

Normal defrost cycles briefly reverse refrigerant flow to melt light frost; this can cause cooler indoor air for a short time but prevents damage. Problematic freezing shows up as thick ice or frost that won’t clear during a normal defrost. Typical causes are blocked airflow (dirty filters, snow-packed cabinet), low refrigerant charge, or failed defrost sensors or controls. Poor siting—units placed too low or near walls that funnel snow—can also contribute. It’s important to tell normal defrost behavior from a fault before attempting fixes.

What Are the Safe DIY Steps to Address a Frozen Heat Pump?

Put safety first: turn the outdoor unit off at the breaker before working near the coils. Do not chip ice off fins—those fins are fragile. Clear loose snow away and let the unit thaw naturally or with warm air. Replace or clean indoor filters to restore airflow and make sure drain paths aren’t blocked. After the unit thaws, restore power and watch a full cycle to see whether it returns to normal. If heavy ice returns within a day or two, document times and conditions and call a technician. These steps reduce immediate risk and give helpful details for a service visit.

- Switch the heat pump off at the breaker before approaching the outdoor unit.

- Carefully remove loose snow and ice around the unit; don’t pry ice off the coil.

- Replace or clean indoor filters and clear nearby debris that blocks airflow.

After these steps, monitor the system through at least one defrost cycle to see if the problem is fixed.

If the unit re-freezes after safe homeowner steps, likely causes include low refrigerant or a failed defrost board—these require professional service.

When Is Professional Service Needed for Heat Pump Freezing Problems?

Call a trained technician when freezing repeats after your safe checks, when you see oil stains (which can indicate a refrigerant leak), or when defrost cycles don’t run correctly. A technician will test refrigerant pressures, check the defrost control and sensors, and verify reversing valve and compressor operation under load. If siting is the issue, they can recommend relocation or protective measures. Refrigerant handling and electrical diagnostics should always be done by a qualified pro for safety and warranty reasons.

Freeze diagnostic table: the chart below compares freeze symptoms, homeowner diagnostics, temporary fixes, and signs that professional repair is needed.

| Component / Freeze Symptom | Freezing Indicator | Diagnostic Step | Temporary Fix | Professional Repair Needed |

|---|---|---|---|---|

| Heavy ice on coil | Thick ice outside normal defrost times | Power down, clear snow, check filter | Allow a slow thaw; restore power and observe | Repeated icing, oil residue, or defrost board failure |

| Frost on refrigerant lines | Frost extending beyond expected areas | Check filter and airflow; listen for compressor | Improve airflow and monitor cycles | Low refrigerant or leak suspected |

| Outdoor unit buried by snow | Unit obstructed and can’t draw air | Remove snow and keep 2–3 ft clear around unit | Keep area clear while storms pass | If the unit re-ices with proper clearance |

This table helps you act safely and shows when a technician should take over.

What Should I Do If My Heat Pump Is Making Strange Noises?

Noises are one of the best diagnostic clues. Different sounds point to electrical, mechanical, or airflow problems and indicate how urgent the repair is. Buzzing can mean electrical or relay issues, squealing often points to worn bearings or belts, and grinding usually signals severe mechanical failure—turn the unit off and get service right away. Start with a visual inspection and safe checks: look for debris, loose panels, or bent fan blades. If you smell burning or see smoke, shut the system down and call a technician immediately. The sections below describe common sounds, safe checks you can do, and when to book professional diagnostics.

What Types of Noises Indicate Specific Heat Pump Problems?

Match the sound to likely parts: buzzing or humming is often electrical—failing capacitors or loose contactors; squealing points to motor bearings or belt issues (on older units); rattling usually comes from loose panels, debris, or mounting hardware. Grinding is a critical warning—stop the unit and call a pro to avoid major damage. Listen during startup and shutdown to help pinpoint whether the noise happens when the compressor engages, the fan spins up, or throughout the cycle.

How Can I Identify and Troubleshoot Noise Causes?

Begin with a careful visual and listening check while the unit runs: look for loose access panels, debris near the fan, or visibly damaged blades. Tightening panels and removing debris will solve many rattles and whines. If the sound seems electrical or you detect a burning smell, switch the system off and call a technician—don’t attempt capacitor or wiring work yourself. When safe, check that the unit is level and that fan blades spin freely when powered down. Note whether noise changes when the thermostat cycles the compressor; these observations help the technician focus tests. Recording when the noise happens and how it sounds speeds diagnosis.

- Inspect the outdoor unit for debris and loose panels.

- With the power off, confirm fan blades spin freely and fasten any loose covers.

- Note if the noise happens at startup, while running, or during shutdown.

Short fixes will solve many noise issues, but electrical buzzing or grinding requires immediate professional attention to prevent bigger failures.

When to Schedule Professional Noise Diagnosis and Repair?

Book a professional when noises continue after simple checks, when you smell burning or see smoke, or when grinding or metal-on-metal contact is suspected. Technicians will test electrical parts (capacitors, relays), inspect motor bearings and mounts, and check compressor health with safe diagnostic tools. Prompt service prevents compressor failure, avoids expensive replacements, and restores safe operation. If a noise is recurring or getting louder, arrange service soon to limit damage and downtime.

What Causes Heat Pump Short Cycling and How Can I Fix It?

Short cycling—many on/off cycles in a short time—hurts efficiency and speeds wear because the compressor never reaches steady operation. Common causes include thermostat placement that lets the system hit setpoint too quickly, electrical faults that interrupt power, incorrect system sizing, and airflow or refrigerant problems that prevent steady heat exchange. The sections below cover signs and risks, typical causes, and safe homeowner checks to identify and reduce short cycling.

What Are the Signs and Risks of Heat Pump Short Cycling?

Signs are frequent starts and stops within minutes, audible cycling, and unstable indoor temperatures even as the system seems to run often. Short cycling increases compressor wear, shortens system life, and wastes energy—raising bills and the chance of premature failure. Tracking how often the unit cycles per hour helps technicians decide the cause and urgency. Fixing short cycling early protects capacity and avoids a costly compressor replacement.

What Common Factors Lead to Short Cycling?

Typical causes: thermostat placed too close to a heat source or return, oversized equipment that reaches setpoint too fast, low refrigerant or restricted airflow that confuses controls, and electrical interruptions like failing contactors that cause restarts. Each root cause points to different fixes—from moving a thermostat to professional refrigerant and electrical repairs.

How Can I Troubleshoot Short Cycling Safely?

Start with safe homeowner checks: confirm the thermostat location and settings (avoid direct sunlight or placement near vents), replace dirty filters to restore airflow, and monitor cycle timing so you can report it. Check breakers for trips and visible wiring for obvious issues, but don’t open electrical panels or test live circuits. If short cycling continues, call a professional to check refrigerant levels, relays, and sizing or control logic. Quick escalation prevents cumulative damage.

Short-cycling reference table: the chart below summarizes indicators, likely causes, safe DIY steps, and risks so you can prioritize actions.

| Indicator | Short-Cycling Sign | Likely Component | DIY Troubleshooting Step | Risk if Unresolved |

|---|---|---|---|---|

| Rapid on/off cycles | Several on/off events in minutes | Thermostat placement, refrigerant, electrical | Move thermostat from heat sources, replace filter | Compressor damage and higher energy use |

| Unit starts but fails to run | Short runtimes followed by immediate stop | Relay/contact, capacitor, electrical | Check breaker and listen for relay chatter (don’t open panel) | Repeated starts stress motor and compressor |

| System reaches setpoint too fast | Short satisfied cycles | Oversized unit or zone imbalance | Review zoning and thermostat programming | Poor humidity control and uneven comfort |

Use this guide to separate homeowner-remediable causes from problems that need a technician.

Why Is My Heat Pump Blowing Cold Air in Heat Mode?

Cold air in heat mode can be normal during a short defrost cycle, but persistent cold output usually signals a reversing valve issue, low refrigerant, or compressor trouble. The reversing valve, defrost control, and refrigerant charge are the mechanical and control parts that determine heat output. Safe checks help confirm mode and cycle behavior; refrigerant and mechanical faults require a professional diagnosis. The sections below explain causes, how to diagnose, and when to call for service.

What Causes Heat Pumps to Blow Cold Air When Heating?

Common reasons: normal defrost operation temporarily produces cool air indoors; a stuck or faulty reversing valve can leave the system in cooling mode; and low refrigerant or weak compressor performance can’t generate heat. Distinguish short defrost events from ongoing cold air. If cool output persists and is paired with long runtimes, odd noises, or unusual frost, a mechanical or refrigerant issue is likely and needs a pro.

How Can I Diagnose and Fix Cold Air Blowing Issues?

First confirm the thermostat is set to heat and the fan is on the right setting. Watch whether the cold air lines up with a short defrost period—if so, that should pass in minutes. If cold air continues, check the outdoor unit for constant defrost behavior, listen for abnormal compressor sounds, and look for oil near service ports (a sign of leaks). If you can, measure vent temperatures and track cycles. If home checks don’t fix it, a technician will test refrigerant charge, reversing valve operation, and compressorcapacity. Common professional fixes include refrigerant recharge, valve replacement, or compressor repair.

When Should I Contact Burkett’s for Heat Pump Cold Air Problems?

Contact us if cold air continues after confirming thermostat mode and doing safe visual checks—or if you see signs of refrigerant leaks, oil residue, repeated breaker trips, or unusual compressor noises. Burkett’s Heating & Cooling serves Miami County homeowners with heat pump repair, replacement, and maintenance. Our technicians can evaluate refrigerant charge, reversing valve function, and compressor condition to restore reliable heating. If you’ve done the homeowner checks above and the problem persists, call or book a diagnostic visit.

How Can Preventative Maintenance Help Avoid Common Heat Pump Issues?

Regular maintenance catches small problems before they grow, improves efficiency, and extends equipment life by keeping filters, coils, electrical connections, and refrigerant systems in good condition. Seasonal tune-ups are especially valuable in Miami County, where winter defrost demand is high. Preventative care reduces emergency repairs and keeps your home comfortable. The sections below explain the benefits, what a local maintenance plan covers, and recommended scheduling to keep upkeep simple and effective.

What Are the Benefits of Regular Heat Pump Maintenance?

Routine maintenance keeps coils clean, filters fresh, and airflow flowing—lowering energy use and monthly bills. It also finds worn components like capacitors, relays, and weak motors before they fail, cutting the chance of emergency breakdowns. Maintenance maintains comfort and indoor air quality and helps you plan equipment replacement instead of reacting to sudden failure. For Miami County homes, a pre-winter tune-up is a smart step to ensure dependable heating.

- Better energy efficiency and lower utility bills.

- Fewer emergency breakdowns and longer equipment life.

- More consistent comfort and improved indoor air quality.

Regular maintenance is a cost-effective way to prevent most common heat pump problems.

What Does Burkett’s Heat Pump Maintenance Plan Include?

Burkett’s Heating & Cooling offers maintenance plans built to prevent the common issues covered in this guide. Our tune-ups focus on inspection and care that keep heat pumps running reliably.

Typical plan items: filter inspection and replacement guidance, coil and outdoor-unit cleaning, electrical connection checks, thermostat and control calibration, and refrigerant system checks when indicated. Plans emphasize durable repairs and scheduled tune-ups that reduce emergency service needs and match Miami County’s seasonal demands. To learn details or schedule a visit, contact Burkett’s using the phone number on our contact page.

How Often Should Miami County Homeowners Schedule Heat Pump Maintenance?

At minimum, schedule a professional inspection and tune-up once a year—ideally before winter to confirm heating readiness and again in spring for cooling prep. Homes with higher usage or known issues may benefit from twice-yearly service. Homeowners should also do simple monthly checks, like inspecting and changing filters, to keep airflow healthy between professional visits. Seasonal scheduling helps prevent freezing problems and keeps systems efficient during peak use in our area.

Why Choose Burkett’s Heating & Cooling for Heat Pump Troubleshooting and Repair?

Burkett’s Heating & Cooling focuses on Miami County homeowners. We offer heat pump service, repair, replacement, and maintenance with an emphasis on prompt, long-lasting repairs and maintenance plans that reduce repeat calls. Our local experience means we understand Ohio weather, common siting issues, and the faults we see most often. We aim to be a helpful source of information and reliable service so homeowners get back to comfortable, predictable heat quickly.

What Local Experience and Expertise Does Burkett’s Offer?

Burkett’s Heating & Cooling was founded by Sam Burkett and later purchased by Thor Penrod. Our team brings deep local experience servicing heat pumps across Miami County and nearby towns like Piqua, Sidney, and Troy. That local focus helps technicians arrive prepared, understand recurring installation or siting problems, and recommend durable fixes. We provide core services—service, repair, replacement, and maintenance—tailored to the scenarios in this guide.

How Does Burkett’s Ensure Timely and Durable Heat Pump Repairs?

We prioritize quick response and durable repairs. Our technicians use clear diagnostics and recommend repairs that address root causes—airflow restrictions, electrical faults, or refrigerant issues—so you don’t keep calling back for the same problem. We tie repairs to maintenance planning so you get fewer emergencies and more predictable system performance. For complex or persistent faults, we recommend thorough diagnostics and proven repair methods to restore reliable operation.

How Can I Contact Burkett’s for Heat Pump Service in Miami County?

To schedule a diagnostic visit, request a repair estimate, or ask about a preventative maintenance plan, call our main number or visit our contact page. Burkett’s Heating & Cooling can be reached by phone call; contact with scheduling and local support. When you call, have available the symptoms you’ve observed, any DIY checks you’ve done, and any safety concerns so the technician can bring the right tools and parts.

When to call Burkett’s:

- After safe homeowner checks don’t restore heating or cooling.

- If you spot refrigerant leaks, oil staining, or smell electrical burning.

- To schedule preventative maintenance or a pre-winter tune-up.

These options help you move from basic diagnosis to professional repair with clarity and local responsiveness.